Unipart Rail and McCulloch Group launch the TRT-e – the first zero-emissions Trac Rail Transposer

Unipart Rail and McCulloch Group have officially launched the first prototype of the new industry-changing TRT-e, a zero-emissions version of the Trac Rail Transposer, the safest and most versatile rail handling machine on the infrastructure.

This first-of-its-kind solution uses an electric motor and battery power pack instead of the traditional diesel engine, and is run via an electronic control system with remote condition monitoring enabling it to be worked more extensively on the rail infrastructure where diesel emissions and noise pollution are a major issue.

The existing diesel-powered TRT is already a low carbon, low emission system, being an EU Tier 4 final engine, however the TRT-e will eliminate up to 80kg of CO2 on a typical operating shift, equating to an annual saving of 650,000kg of CO2 within McCulloch’s UK operations.

The launch took place during demonstration events held last month at the Network Rail RIDC (Rail Innovation and Development Centre) in Tuxford. During the event, customers had the opportunity to see the TRT-e demonstrated live within a test track environment which demonstrated the capabilities of the equipment and the enhanced benefits in terms of environmental impacts and carbon footprint reduction.

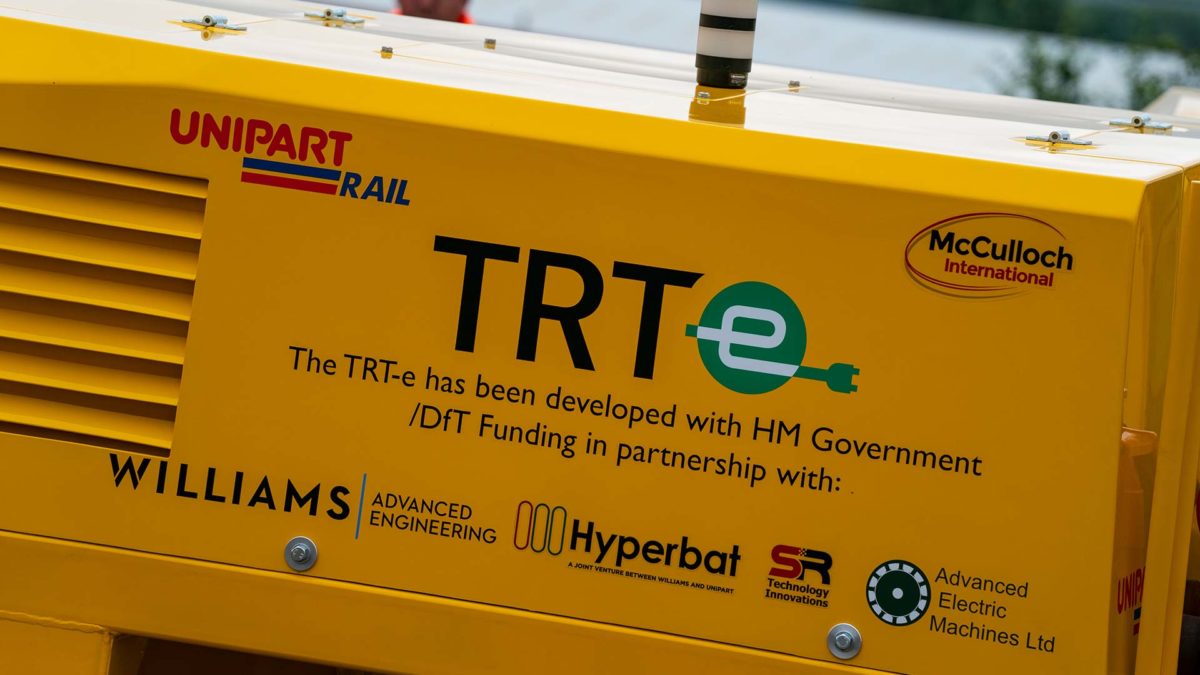

The funding for the TRT-e project was provided by the Department for Transport and delivered in partnership with Innovate UK as part of the 2020 First of a Kind (FOAK) competition, which has awarded funding to innovative projects that will make railways cleaner, greener and more passenger-friendly.

Unipart Rail was selected as the winner in the Environmental sustainability category, receiving a share of the £9.4 million awarded to 25 pioneering projects.

Manufactured at the Unipart Rail site in Crewe, the TRT-e has been developed in partnership with expert partners including McCulloch Group, Hyperbat, Williams Advanced Engineering, Advanced Electric Machines, and SR Technology.

This pioneering project supports the Unipart Group objective to achieve carbon neutrality by 2030, with the strategic intent of becoming net zero before 2050.

David Girdler, Chief Executive Officer, McCulloch Group commented:

“McCulloch’s innovative and patented methodology of lifting and manipulating rail within the footprint of the TRT machine optimises efficiency, requiring far lower power requirements when compared to equivalent traditional rail plant which is often converted construction plant. This principle has enabled the development of a battery equivalent – the TRTe – which builds on the hugely successful and already efficient diesel powered TRT without compromising on operational performance or reliability.

“At McCulloch Group we are driven by operational and environmental considerations and the development of the TRTe will further revolutionise trackwork efficiency in an even more sustainable manner.

“We are excited to be putting this technology into production, along with the opportunity to transfer this innovative power source to all of our equipment solutions in the near future.”

Neil McNicholas, Managing Director, Unipart Rail commented:

“The collaboration between Unipart Rail and McCulloch, and our combined knowledge, technical expertise, and manufacturing capability, provides us with the opportunity to offer a unique solution to customers. This enables them to reduce their operational costs, enhance safety, and improve productivity.

“The TRT-e is a first-of-its-kind solution for the rail industry and will have a huge impact on our customers’ operations. We look forward to introducing this technology across the wider range of McCulloch products in the future, in order to support customers in their journey to implement sustainable solutions and reduce their carbon footprint.”

More Information about the TRT-e

The TRTe (Trac Rail Transposer) is a rubber-tracked machine suitable for use on rail infrastructures, underground track and light rail networks. The TRT-e is 2.5 metres long, 1.8 metres in width and 1.6 metres in height making it a compact and easily transportable unit for limited access locations. The machine can remove and install all profiles of rail including Bull Head, Flat Bottom Rail and Conductor Rail.

The TRT-e can be used to re-position any length of plain line rail from 6m (20ft) up to 425m (1418ft) and can also be utilised to transport, remove and install any length of switches and crossings (S&C) associated iron work.

- Fully approved to work under live Overhead Line Equipment.

- Removes, installs and repositions rail in a safe controlled manner.

- Ideal for use on single line track layouts.

- Can easily cross multiple tracks including areas with conductor rails.

- Capable of threading rail past lineside equipment/masts etc from one track to another

About Unipart Rail

Unipart Rail is the leading specialist provider of technology and supply chain solutions to the rail industry. With a growing international presence and extensive expertise in infrastructure, signalling and traction and rolling stock products, Unipart Rail is a major partner to the rail industry.

Unipart Rail is part of the multinational Unipart Group, with headquarters in the United Kingdom and operations in more than 100 countries.

Unipart Rail companies also include:

- Unipart Dorman – LED signalling and indication innovators and manufacturers

- Park Signalling – signalling design and consultancy specialists

- Instrumentel – remote condition monitoring specialists for high performance engines and rail applications

- Key Fasteners – vending and software solutions to supply and track fasteners from the manufacturer to the train

- Samuel James Engineering – suppliers of LV switchgear and control gear systems for the Rail Industry

- Westcode – a UK and US company with an extensive range of air supply equipment.

About McCulloch Group

Founded in 1992, McCulloch Group has established itself as a leading player in the UK rail Industry, designing, developing and operating unique rail and railway component handling equipment with a commitment for continuous improvement and innovation being at the forefront of the Company’s Strategy.

Building on this UK pedigree, and supported by Unipart Rail, McCulloch Group’s products and solutions are now being distributed globally, and already in active use with customers in the United States, Canada, Australia, New Zealand and Malaysia.

Partner Information

Hyperbat

Hyperbat is a joint venture between Unipart and Williams Advanced Engineering (WAE) and was formed to manufacture innovative high voltage battery solutions for specialist applications. WAE have designed and manufactured a ‘one-off’ battery bespoke for this application and Hyperbat are now looking to commercialise a production version going forward.

Hyperbat

Hyperbat is a joint venture between Unipart and Williams Advanced Engineering (WAE) and was formed to manufacture innovative high voltage battery solutions for specialist applications. WAE have designed and manufactured a ‘one-off’ battery bespoke for this application and Hyperbat are now looking to commercialise a production version going forward.

SR Technology Innovations

SR Technology Innovations was brought into the project to develop the control system, sensors and monitoring. Remote data monitoring has been built into the control system and display screens added to the front of the machine and the remote handset that will show basic data.

About Unipart Group

Unipart Group is a leading UK manufacturer, full-service logistics provider, and consultant in operational excellence. Operating across a range of market sectors, including automotive, manufacturing, mobile telecoms, rail, retail and technology, Unipart offers a breadth of services from third-party logistics to expert consultancy. The company, which has its headquarters in Oxford, provides services to a growing range of blue-chip clients including Jaguar Land Rover, Vodafone, Sky, and many other household names.

More in Manufacturing

Intertronics: Driving Innovation in Adhesives and Assembly Solutions

For over four decades, Intertronics has been at the forefront of providing high-performance adhesives, coatings, sealants, and application equipment to industries that demand precision and reliability. From electronics and medical devices to automotive and aerospace, Intertronics’ expertise ensures that manufacturers can optimise their bonding and assembly processes with cutting-edge solutions.

Unipart named CCS supplier

Unipart has been named as a supplier on Crown Commercial Service’s (CCS) Logistics, Warehousing and Supply Chain Solutions (RM6329) framework agreement.

Owen Mumford: 70 Years of Innovation in Healthcare

Owen Mumford has been at the forefront of medical device innovation for over 70 years, pioneering solutions that enhance patient care and improve healthcare outcomes worldwide. Established in 1952 by Ivan Owen and John Mumford, the company has grown into a global leader in medical device design and manufacturing, with a commitment to quality, sustainability, and patient-centred innovation.

From this author

Unipart announces record performance for year ending 31 December 2024

Strong year of growth & expansion, celebrating 50 years of the Unipart brand

Unipart named CCS supplier

Unipart has been named as a supplier on Crown Commercial Service’s (CCS) Logistics, Warehousing and Supply Chain Solutions (RM6329) framework agreement.

Unipart partners GBUK

Unipart has formed a strategic partnership with GBUK